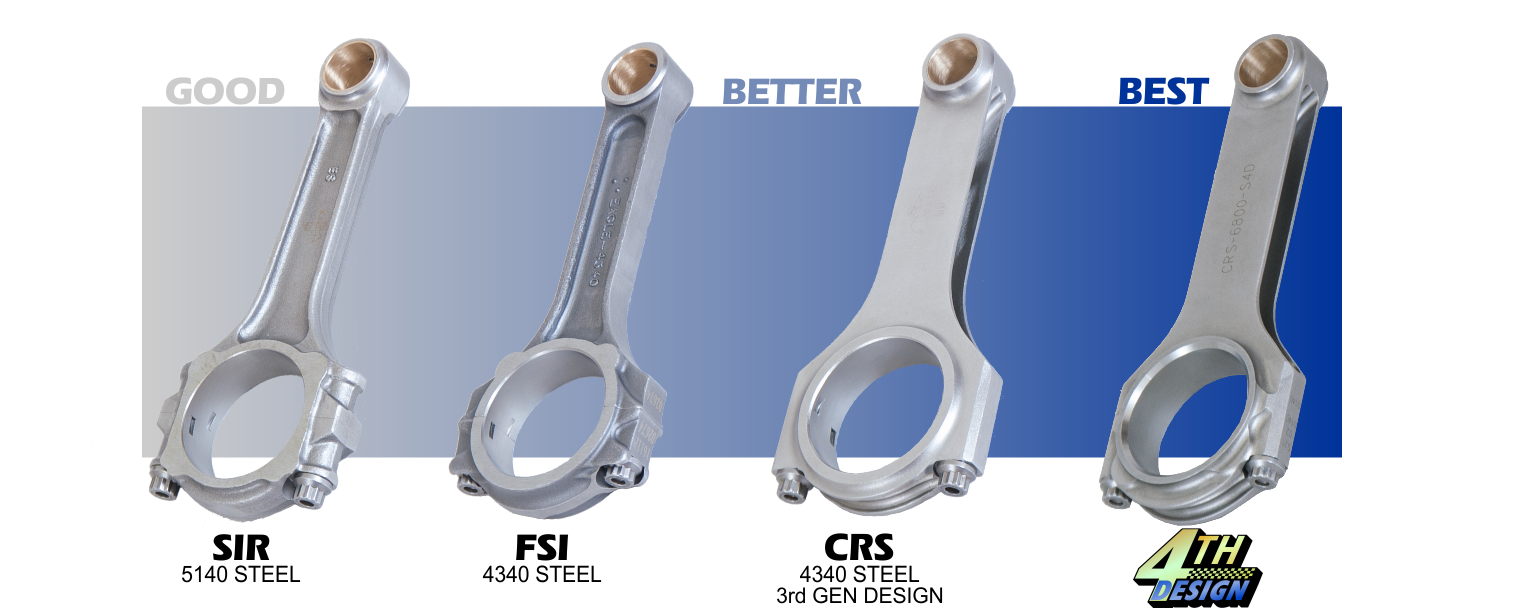

Eagle offers several different types of connecting rods for many different applications. Our "SIR" forged 5140 steel I-Beam rod is intended to be a good alternative to reconditioning O.E. rods. In many cases, Eagle "SIR" rods are a little stronger than O.E. rods depending on which O.E. you compare them to. Not intended for competition use, we generally recommend them for use up to about 500hp in a small block and 700hp in a big block.

Eagle "FSI" forged 4340 steel I-Beam rods are a performance-oriented I-Beam rod. 7/16" ARP 8740 bolts are used in every application. Costs are kept low by using the rod "as-forged" on non-critical surfaces. That, coupled with the easy-to-manufacture I-Beam design makes the "FSI" rod an excellent choice for naturally-aspirated competition engines. Upgrade to ARP 2000 bolts for high rpm capabilities. "FSI" rods are recommended for use up to 750hp.

Eagle's 3rd generation design (3D) H-Beam rods are the measure by which all other connecting rods on the market are measured. Eagle utilizes large-scale manufacturing to keep costs low, but only uses ASME-certified 4340 steel, ARP bolts, and silicon-bronze bushings. Eagle H-Beam rods are the preferred choice for high horsepower, high RPM competition engines utilizing nitrous, forced induction, or exotic fuels. The rod itself is recommended for use up to about 1500 hp. The ARP bolts required to handle that are ARP's L19 bolts. 1500hp is a lot more than a lot of people need, so Eagle H-Beam rods are also offered with much less expensive ARP 8740 bolts or ARP 2000 bolts. Eagle H-Beam rods with 7/16" ARP 8740 bolts are recommended for use up to 800hp. With 7/16" ARP 2000 bolts, 1300hp (V8), with L19 bolts, 1500hp. Eagle's H-Beam rods for most sport compact applications feature 3/8" ARP 2000 bolts. These are recommended for use up to 900hp (4 cyl) and 1500hp (6 cyl) in turbocharged applications. For even more power-handling capabilities, see out Extreme Duty connecting rods for sport-compact applications.

Eagle Extreme Duty (XD) rods feature the same time-tested 3rd generation design, but further surface polishing improves fatigue life by removing microscpic pits and inclusions where fatigue cracks begin. In addition, ARP's premium fastener material, Custom Age 625+, is used. ARP Custom Age 625+ material oasts a typical tensile strength of 245,000 psi vs. ARP 2000's 220,000 psi. It comes with a heafty price tag, though. The rods are not for the faint of heart. Power ratings have not been established for these rods. Honestly, we just haven't had any fail yet. They are not indestructible, though. We feel the power capabiities to be somewhere in the 1200 hp range for 4 cyl. applications and 1800hp for 6 cylinder applications.

And now, at long last, Eagle has introduced our 4th generation design (4D) H-Beam rods. Racers are making more power now than ever before and the bottom end has got to be up to the task! Eagle 4D rods are designed to handle all the power you can make without breaking the bank. Design advancements include thicker webbing and thicker beam to improve tensile and compressive strength. The big end of the rod also sees several design improvements. Material has been added at the parting line, at the bolt head clamping area, in the "shoulder" of the rod, and the webbing on the cap is significantly strengthened. This improves big end rigidity tremendously. Under very high loads, the big end of the rod can become distorted ("egg-shaped") causing a loss in oil film consistency eventually leading to a breakdown in support for the bearing and spinning a rod bearing. Adding material in these areas solves this issue in very high power applications. All Eagle 4D rods come standard with 7/16" ARP 2000 bolts - even 4 and 6 cylider applications! This is a 36% increase in bolt strength alone for those applications! All Eagle 4D rods are 100% CNC machined. Every surface! This provides unrivaled consistency in manufacturing that is unmatched by any large-scale manufactured rod. Finally, Eagle 4D rods are forged from a steel that has been 30 years in development. "4340" is an alloy formula conceived by The American Iron and Steel Institute (AISI) and adopted by the Society of Automotive Engineers (SAE) and the American Society of Mechanical Engineers (ASME). It is the material of choice for connecting rods and crankshafts in the high-performance industry. Eagle has spent the last 35 years establishing a very good relationship with our steel foundry of choice and when you buy as much steel as we do, they will start listening to special requests. While 4340 is very good standard to start with, like everything, it can always be improved upon. Not just in sheer strength, but modulus of elasticity, area reduction under stress and other properties. While we can't go into too much detail, know that Eagle is constantly tinkering with the alloying "formula" and heat-treatment process that goes into our steel. We are thankful that our foundry has entertained our requests and we are very pleased with the result. The steel we use in our 4D rods exceeds ASME 4340 in several areas: tensile strength is higher than typical 4340 steel, fatigue strength due to cyclical loading is improved, modulus of elasticity is improved significantly as is area reduction under stress. The specifics concerning all of this is obviously a very closely guarded secret. Gone are the days of "off the shelf 4340". We haven't named our proprietary alloy yet - the results were more important than the marketing. We are confident the results will speak for themselves. Eagle 4D rods will prove themselves to be the strongest rods on the market - at ANY price!